Electric vehicles are all the rage nowadays, and manufacturers are trying to one up each other every day as to who can fit the most

efficient or the largest battery pack in an EV

. But despite battery advancement moving forward so quickly, the 12V battery has remained more or less the same and EVs are still equipped with them despite having such a massive high capacity battery powering its motors. While EV manufacturers have tried to alter almost all aspects of a vehicle to be more suited to electrification, they have choses to stick with the 12V system still.

Now, there are many reasons as to why manufacturers still use 12V batteries in EVs. Most of it boils down to the safety and complexity of trying to supply such small currents efficiently. Some functions of the vehicle, like door locks and lights, need to work no matter what and the 12V battery is an easy solution which fulfills both purposes without causing much hassle and maintaining the ease of use even on new high-tech vehicles. An

EVs battery is also one of the most expensive component

in the vehicle and there is some cost-effectiveness involved as well, but we have seen some pretty expensive EVs which still incorporate the 12V battery.

Read more:

8 Enthusiast Cars That Are Absurdly Overrated

The Use Of 12V Batteries In Modern EVs

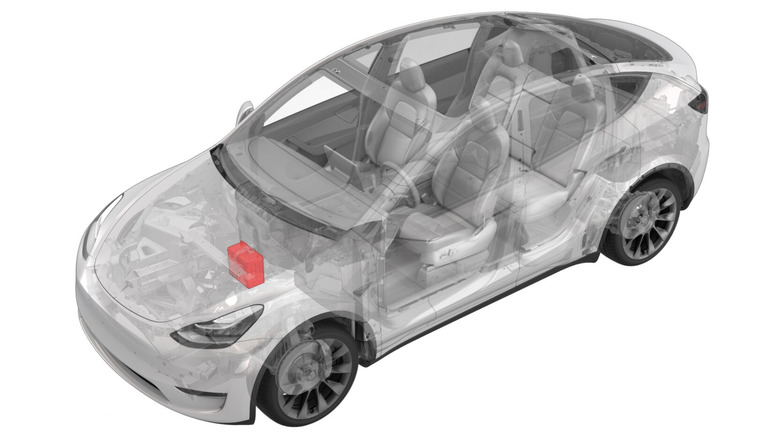

Let us first learn what these batteries are powering to understand the need for them better. Just like in regular ICE cars, the 12V battery in EVs power some of the most vital components of the vehicle. This includes the lights, horn, door locks, windows, power steering, infotainment system and any other low voltage items. This also includes the ECU (Electronic Control Unit) or the brains of the vehicle which powers all the aforementioned components as well as the driveline componentry of the vehicle.

Now, manufacturers like to use

several types of batteries in an EV

, but most of these batteries powering the 12V system of the vehicle are of the lead-acid type, which have been used in vehicles for several decades now. The batteries are cheap, easy to maintain and quite reliable, but some of the modern cars do use a lithium-ion battery for the 12V system as well, which allows for lighter weight and better performance.

Lithium-ion batteries also have significantly greater longevity compared to lead-acid batteries. Despite the type of battery utilized to supply power to the low-voltage systems in vehicles, the 12V system remains widely recognized and easily managed, even within electric vehicles.

Why Do Electric Vehicles Still Include a 12V Battery?

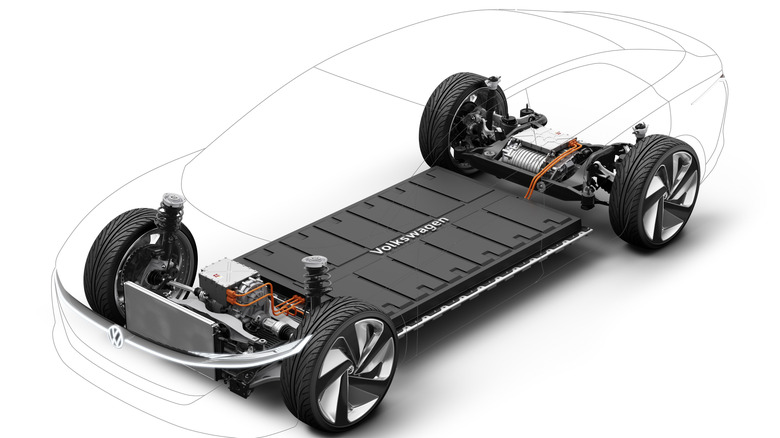

Replacing a 12V battery system in an EV is not only quite complex, but will in terms waste a lot of energy as well. Most EVs run on a high voltage architecture, which is used to power the electric motors of the vehicle. The high voltage batteries are usually rated at 400V or 800V. To produce components which work with this higher voltage would be an immensely painful task. The energy required to convert the higher voltage output to a lower voltage to run 12V systems in a car will cause greater inefficiencies as well, causing more wastage of energy than it would be to have a separate battery to power the low voltage electronics.

Safety concerns play a significant role in shaping the design of contemporary automobiles. By incorporating dual battery systems, manufacturers can isolate the high-voltage battery and related parts from those operating at lower voltages. As such, the area occupied by passengers contains no high-voltage elements—a key aspect during collisions. In case of accidents, these large batteries facilitate quicker disconnection. Meanwhile, essential features including lighting, door locks, advanced driver assistance systems (ADAS), airbags, and electronic control units continue receiving power. This setup significantly simplifies matters for emergency personnel as they won’t have to contend with hazardous high-voltage currents within the vehicle.

Finally, another aspect to consider is streamlining the production process for vehicles. Many automotive parts suppliers have been producing 12-volt systems for conventional cars, which can be readily incorporated into newer electric vehicles with advanced technology. This integration makes both the manufacturing process faster and simpler, and more cost-effective for producers.

Interested in staying updated with the newest technology and automotive developments?

Sign up for our complimentary email newsletter.

for the latest headlines, expert guides, and how-to tips, one email at a time.

Read the

original article on GAPTEKZONE

.